No matter what your operational needs are, VisionLink can help you reduce costs and increase efficiency.

Features and Benefits

The VisionLink solution from Trimble integrates site productivity, material quantities, and materials movement with asset and fleet management to give you a holistic view of your site so you can make the right decision at the right time. Centralizing and simplifying the management of on-site operations maximizes efficiency, raises productivity and lowers costs for your entire fleet.

- Know when and where your equipment is working

- Examine asset utilization and minimize idle times to reduce equipment depreciation and eliminate unnecessary and costly fuel burn

- Monitor excavator and wheel loader payloads and optimize haul operations

- Manage and make informed decisions about production efficiency

- See continuously updated surface models based on machine activity

- Scheduled reporting of business-critical information like volume and quality assurance data for easier and more accurate billing, inspections and project progress

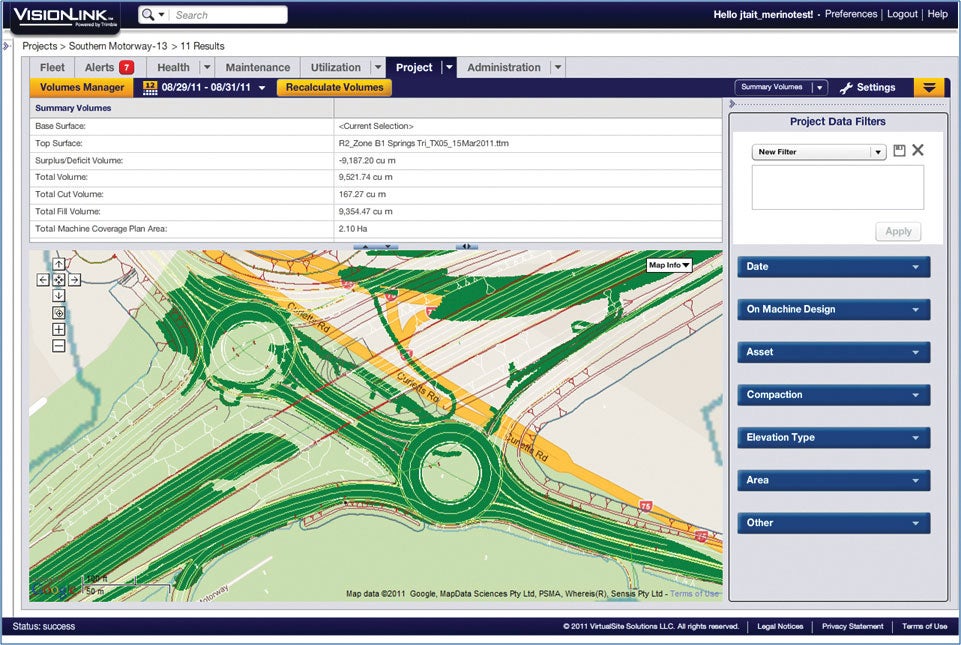

2D Project Monitoring

- Monitor cycle times and load counts to track actuals against planned and monitor job site productivity

- Track materials movement to remove contaminated materials from the site, and use structural and non-structural materials in the correct site location

- Rectify problems in a timely manner and estimate completion times more accurately to keep jobs on schedule

- View individual machine performance or aggregate fleet data to see an entire site at a glance. Maintain production schedules by monitoring productivity against plan and making decisions in near real-time

- Customize the dashboard and only see information that is important to you

- Configuration

- Requires the Trimble SNM940 Connected Site Gateway

- Includes VisionLink Asset and Fleet Management Universal subscription plan and VisionLink Mobile

3D Project Monitoring

Earthmoving and Grading:

- VisionLink continuously monitor and record 3D earthmoving, grading and finishing operations throughout the life of the project, and use the information to make timely decisions regarding equipment use and deployment

- Create near real-time 3D surface model, elevation and cut and fill maps to show progress towards completion, eliminate drive time to the site and ensure you have the most current information

- Accurately capture all work completed including over-excavation and backfill, overfill or surcharge, and cut back operations so you get paid for the extra work you do

Compaction

- VisionLink continuously monitor pass counts and compaction meter values over the entire area of compaction and on all material layers to improve testing success, reduce rework and lower ongoing maintenance costs

- Reduce over-compaction to optimize fuel use and machine time, and increase the finished surface quality

- Ensure uniform lift thicknesses and consistent compaction pass counts and meter values to increase the surface quality and operational life

- Monitor temperature maps for asphalt compactors fitted with temperature sensors to ensure compaction per the temperature range specified on the project